Flexible Sourcing

Our fuel can take any source of low-carbon ethanol – from ag waste, municipal solid waste, to carbon emissions, and more – enabling global production that leverages local, sustainable supply sources.

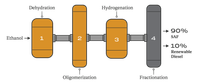

Flexible Product Mix

Our process can operate in maximum jet or diesel modes. That flexibility lets us meet varying production and market demands for these two high-value products.

]

]